Letterpress using wooden blocks| Quality Printing London

7 October 2016

What’s old is new again at Solways! This week we’ve been doing some letterpress printing with wooden blocks and it made us feel all nostalgic for the early days, so we thought we’d have a look back at the history behind the process that changed everything…

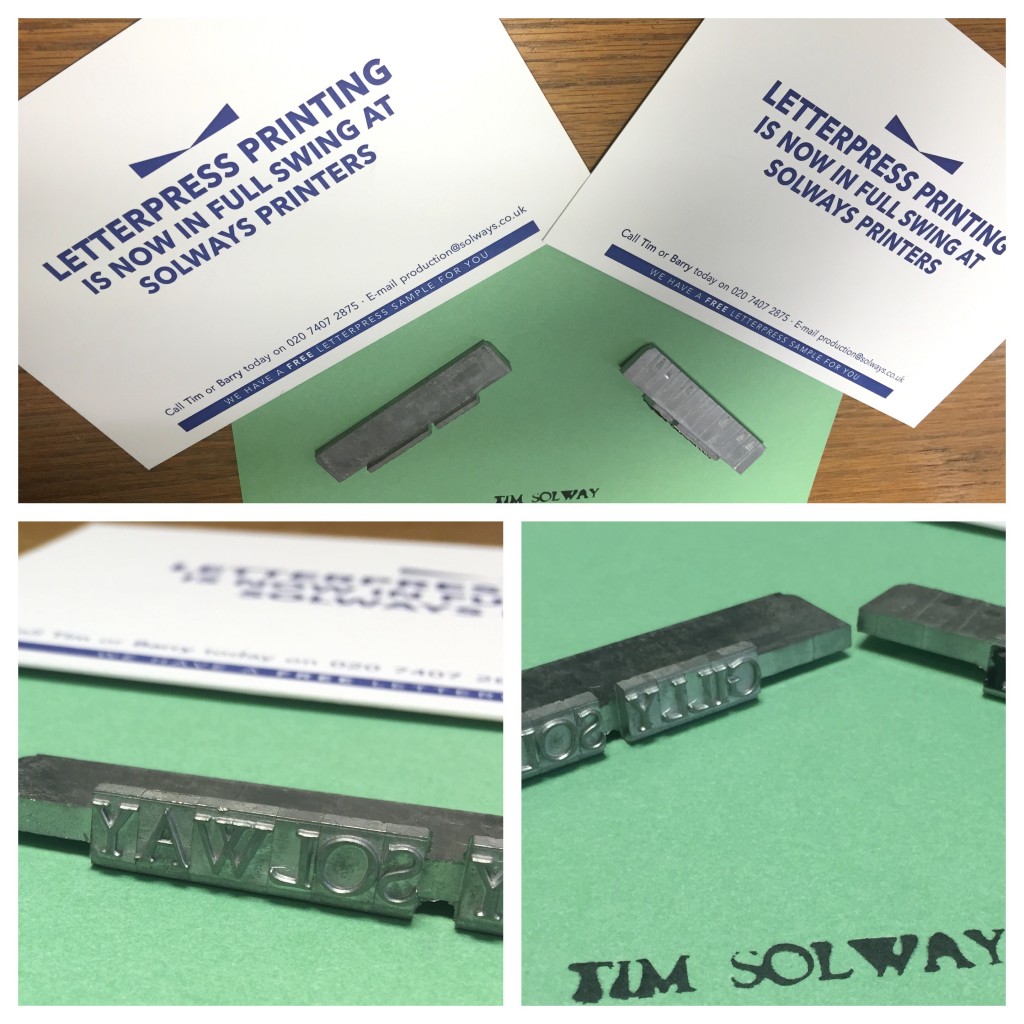

Wooden blocks we’ve been using for letterpress printing this week

Invented by Johannes Gutenberg in the 15th century, letterpress was the standard form of all printing up until the 1800s, and came to affect everything about the way that data was collected and distributed, transforming the way businesses operated and the accessibility of information for everyone. It continued as a standard printing method for books, newspapers and other forms of print media right up until the mid-20th century when offset printing was developed and came to take its place.

In its early days letterpress printing involved individually cast, reusable wooden letter blocks set together in a frame (effectively the first wooden printing presses) whereby the surface of the letter was covered with ink and the paper placed on top, while pressure was applied from above by a large threaded screw to create the print. One of the first jobs for Gutenberg’s “Screw Press” was to print 180 copies of the Bible, which at over a thousand pages each, took him and his team of 20 staff almost 3 years to complete. While this might seem like a long time it was still much quicker than the previous duplication method (which would have meant producing 180 handwritten manuscripts!) and so it didn’t take long for letterpress printing to fill most mass-reproduction requirements.

Of course as the demand for mass printing grew, new faster and more efficient processes were required. First the metal presses came into play, replacing the screw with a knuckle and lever arrangement, then came the introduction of ink rollers, which lead the way for more automated processes closer to those used in printing presses today.

Although the amount of letterpress printing carried out has substantially declined since the mid-20th century it has recently enjoyed somewhat of an artisan revival. So much so that in 2015 we relaunched our letterpress processes and have since taken great pride in helping to preserve such an important part of our industry’s history. It’s really remarkable to think that, despite the developments in technology, the principles behind letterpress printing have remained the same from way back when Gutenberg first conceived them in 1440!

If you’re interested in our letterpress printing services get in touch for further info 020 7407 2875 sales@solways.co.uk

Solways Printers offers print processes away from the mainstream. Our specialties encompass specialist print processes: duplexed (THICK) business cards, triplexed (EXTRA THICK) business cards, watermarking, foil blocking, embossing, digital embossing, Indigo digital, die–cutting, thermography, lithography, Book production and Magazines.